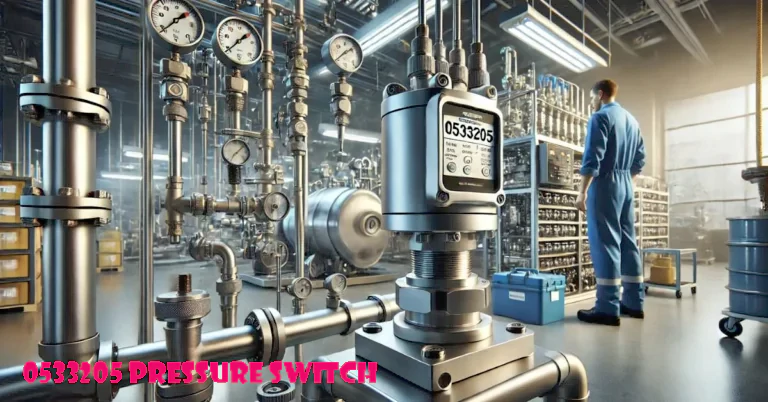

The 0533205 pressure switch is a control device used to detect and respond to pressure changes within mechanical systems. It activates or deactivates electrical circuits based on specific pressure thresholds. While this particular model number may not be widely documented online, it’s often used in industrial equipment and specialized machinery.

Pressure switches like the 0533205 help protect systems from pressure extremes. They can trigger alarms, shut off power, or start equipment when pressure goes above or below set limits. This function makes them vital for maintaining safe and stable operations.

The model number 0533205 could belong to a custom, OEM (original equipment manufacturer), or niche industrial product line. Because of this, finding exact technical details usually requires referring to a parts manual or contacting the manufacturer.

Despite limited public data, the basic working principle and typical uses of such pressure switches remain similar across industries. Understanding its function helps with safe use, accurate replacement, and proper installation.

Technical Overview of the 0533205 Pressure Switch

Pressure switches work based on a setpoint pressure. For the 0533205 model, the internal mechanism likely uses either a diaphragm or piston to detect pressure changes.

In a normally open switch, the contacts close when pressure rises, completing the circuit. In a normally closed switch, the contacts open when pressure rises, cutting off the circuit. This allows precise control in pressure-sensitive environments.

Its electrical specifications likely include a voltage rating (such as 12V, 24V, or 120V) and current handling capability (often up to a few amps). The switch must be matched with the equipment’s electrical system for safe performance.

Material construction plays a key role in durability. The 0533205 might feature corrosion-resistant metals like brass or stainless steel, especially if used in fluid-based systems. The housing is likely sealed to prevent moisture or dust from interfering with internal parts.

Applications and Industry Use

The 0533205 pressure switch is suited for several industrial and mechanical uses. It’s most commonly used in systems that require precise control of air, gas, water, or oil pressure. These systems often include heavy machinery, HVAC units, and automotive equipment.

In HVAC systems, pressure switches monitor refrigerant levels to ensure proper cooling or heating cycles. If pressure drops or rises unexpectedly, the switch will interrupt the system to prevent damage or unsafe operation.

In hydraulic or pneumatic systems, this type of switch helps maintain pressure levels. It prevents overpressure that could damage hoses, valves, or pumps. In some setups, it may trigger backup systems or shut off motors.

Vehicles and trucks might use a switch like this in braking or transmission systems. It’s also used in industrial manufacturing equipment where automated machinery relies on pressure control to function efficiently.

Because of its potential OEM classification, this specific model might only be compatible with certain branded systems. Always check the equipment’s manual or labeling before choosing a replacement.

Installation and Connection Guidelines

Installing a pressure switch like the 0533205 involves both mechanical and electrical setup. The mechanical side requires mounting the switch at the correct location where pressure can be accurately detected—usually a pipe, tank, or pressure line.

Threaded mounting is common. The switch’s threads must match the pipe size, often using NPT or BSP standards. It’s important to use sealing tape or gaskets to avoid leaks after installation.

The electrical connections vary by model. Some use spade connectors, others use screw terminals or specialized plugs. Always ensure the power is turned off before wiring the unit. A mistake during wiring can damage both the switch and the equipment.

Correct orientation matters too. Some pressure switches need to be mounted vertically to function properly. Following the manufacturer’s installation instructions is critical for safe and efficient use.

Maintenance and Troubleshooting

Regular maintenance of the pressure switch ensures it continues to operate reliably. Over time, dust, oil, or corrosion can build up, especially in industrial environments. A quick inspection every few months helps catch potential issues early.

If a system behaves oddly—starts too late, stops suddenly, or doesn’t respond—the pressure switch might be at fault. One way to check is by using a multimeter to test electrical continuity while applying and releasing pressure.

Other signs of trouble include leaks around the threads, cracked housing, or electrical sparking. Sometimes, pressure calibration drifts over time, requiring fine-tuning or replacement of the switch.

To prolong lifespan, avoid exposing the switch to vibrations, direct water spray, or extreme heat unless it’s rated for such conditions. Keeping the switch clean and dry is the easiest way to ensure consistent performance.

Comparisons with Similar Pressure Switches

Not all pressure switches are the same. The 0533205 may have specific setpoint limits or electrical ratings that make it different from more generic models.

If you’re replacing it, compatibility is more than just the mounting thread—it includes pressure range, voltage, and signal type.

Universal pressure switches exist, but they may lack the precision or safety certifications of OEM parts. For critical systems like HVAC compressors or brake controllers, the exact model match is often essential.

Compare the pressure range (e.g., 0–150 psi), switching action (NO/NC), and voltage capacity (AC or DC) when looking for alternatives. It’s also wise to match the material type if it’s exposed to corrosive fluids or gases.

If a datasheet or manual is available, comparing specs line-by-line ensures you get the safest and most reliable substitute. When in doubt, contact a supplier or technician for advice.

Where to Find or Purchase the 0533205 Pressure Switch

Finding the 0533205 pressure switch can be easy if you know where to look. First, check with the equipment manufacturer—they often sell parts directly or through licensed distributors. Some parts are only available through those channels.

You can also search industrial supply websites like Grainger, RS Components, or Allied Electronics. These sites allow you to filter by model number, pressure range, and connector type.

Marketplace platforms like Amazon and eBay may have listings, but be careful of refurbished or misidentified items. Always double-check product photos and part numbers.

If the part is discontinued or rare, try contacting a surplus industrial equipment supplier or a local machinery repair shop. They often stock older parts or can recommend reliable alternatives.

Conclusion

The 0533205 pressure switch plays a small but vital role in pressure-sensitive systems. It ensures machines operate within safe limits, triggering responses that protect equipment and people.

Although specific data may be limited, understanding how these switches work makes it easier to maintain or replace them.

Always choose the right model by confirming compatibility with your system. Install the switch carefully, maintain it regularly, and troubleshoot wisely to extend its lifespan.

Whether you’re a technician or machine operator, knowing how the 0533205 pressure switch functions helps you keep everything running smoothly.

Also Read:

janell kochevar with element 3: Where Marketing Meets Mission-Driven Communication

Tiwzozmix458 for Businesses: Streamlining E-commerce and Data Flowv

That-bites.org foodies: A Delicious Destination for Culinary Enthusiasts

Greece Katz Martian: Culture, Art, and Unexplained Visions

Quotela.net: A Modern Destination for Daily Inspiration, Quotes, and Lifestyle Trends

#mobilecreativeorg: The Rise of Mobile-First Creativity Worldwide